We are leading tin can makers of the Indian Subcontinent with 60 years of packaging experience making 100 million cans to 200+ million cans yearly. Our success has hinged on us guaranteeing quality & delivery due to which we enjoy a marquee customer base of global, regional, and local niche brands. Today we employ 500+ people across 4 facilities in India.

Uncompromising Commitment to Quality

Deep impact on market through Innovations

Employing 500+ people across 4 facilities

Global presence, 400+ customers

20+ cr. cans

60+ yrs legacy

500+ customers

4 plants

15+ Countries

5% savings | 1.5x stronger

The Canmaker Award, UK

CanTECH, Asia

Tata Tin Plate Award

Only other plant in India with mandated

BIS & FSSC certifications

We have four manufacturing facilities in different places- Saharanpur (UP), Roorkee (UK), and Vadodara (Gujarat). Our facilities are installed with sophisticated machinery procured from across the globe.

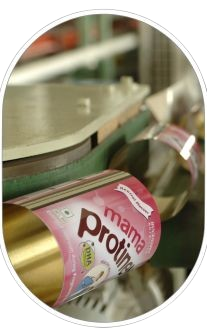

At JJ Enterprise, we are backed by sophisticated infrastructural facilities. We manufacture over 200 million can ends yearly. It helps us meet the growing packaging demands of global FMCG, pharma, dairy, and chemical brands.

We do stringent quality testing for each of our cans and tin boxes. It starts from the procurement of raw materials and continues till the production and final dispatch. Our varied quality certifications – ISO 9001:2015, ISO 22000, FSSAI, BIS and BRCGS – are enough to show how serious we are about our product quality and safety.

At JJ Enterprise, we offer cans and tin boxes for beverages, food, dairy, aerosols, pharmaceuticals, paint, snacks & gifting, and chemical brands according to their exact requirements.

For over 60 years, we have been the leading tin can manufacturer in India, empowering global brands with uncompromising packaging solutions. It has happened due to our infrastructure excellence in the tin can manufacturing industry.

We have four production plants in India based at Roorkee (UK), Saharanpur (UP), and Vadodara (GJ). These facilities are installed with state-of-the-art machines, tools, and equipment procured from across the world. Our flagship unit in Saharanpur has established us as the largest tin can manufacturer in Delhi and tin can manufacturer in Noida, delivering a wide array of tin cans in several different sizes, shapes, and finishes.

Our latest unit in Vadodara (GJ), caters to major clients in West and South, such as Amul, and GRB, making us a top choice of tin can manufacturer in Mumbai and western India, as well as a preferred choice of tin can manufacturer in Bangalore and southern India.

Our Research and Development team is dedicated to offer new, innovative and customised packaging designs and solutions for businesses in the food, dairy, gifting, pharmaceutical, chemical, and many more industries. We have been awarded at domestic and international levels for our patented innovative can designs and superior printing quality. Due to this, we are the most trusted tin can manufacturer in Mumbai, Delhi, Bangalore, pan-India, and worldwide.

At JJ Enterprise, we have ISO 9001:2015, FSSAI, BRCGS, BIS and many more certifications for food-grade tin can manufacturing. It reflects our commitment to quality and process management. With a stringent quality control division, every tin box undergoes a series of stringent quality tests.

You can also click here to connect with a trusted Tin Box Manufacturer today.

Leading Tin Can Manufacturer in India since 1963.

Mail Us

Phone

339, Ground Floor, Patparganj Indl. Area, Delhi-110092

4 Manufacturing units in Roorkee (UK), Saharanpur (UP), Vadodara (GJ)

Copyright © 2024 JJ Enterprises. All Rights Reserved.